Learn how diamonds are cut with expert insights from Abercrombie Jewelry. Discover everything you need to know about the diamond-cutting process and techniques.

Diamonds are the most sought-after gemstone in the jewelry world for their beauty and versatility- but they don’t come out of the mine looking flawless and shiny. Diamond cutting is the process of turning rough stones into sparkly little treasures to be used in rings, earrings, and much more.

How are diamonds cut, and what is the process of taking them from their natural state to ready-to-sell? Here is everything you need to know!

A Few Key Facts about Diamond Cutting

Here are a few fun facts before we get into the techniques and processes used in cutting diamonds.

A Diamond Cutting Tool is Made Using Diamonds

Diamonds are so strong that only a diamond can cut them. As such, the tools used to make diamond cuts are made from diamonds or lined with diamond dust.

Some lasers have been designed to cut through diamonds, but they are not common practice in the jewelry industry.

Hand-cutting a Diamond can Take Months

Many hand-cut diamonds take up to six months to complete- especially if they are made into some of the more intricate shapes.

In some cases, it can take even longer. One stunning pear-shaped diamond sold at Christie’s in 2013 took an incredible 21 months to cut and polish.

There are Two Main Ways to Cut a Rough Diamond

Although rough diamonds can be cut into many shapes and styles, they all fall into one of two categories: brilliant cut and step cut.

Brilliant cut diamonds are polished into a round cone shape with a brilliant shine. Some famous examples include the princess diamond cut, round brilliant cut diamonds, and pear cut diamonds.

Step-cut diamonds are created by cutting square or rectangular facets that sit on top of each other like little stairs. Asscher and emerald-shaped diamonds are two of the most common step-cut diamonds.

It Can Take Decades to Become a Master Diamond Cutter

Learning to cut diamonds may only take a course spanning several months, but the qualifications and experience needed to become a true master diamond cutter can take people up to 20 years or longer. Anything less than five years is not enough to gain the skills required to earn this title.

The Four Diamond Cutting Techniques

Read More: A Short but Comprehensive Guide on How to Find the Best Place To Sell Gold in Austin, Texas

Professional diamond cutters use four key techniques in the diamond-cutting process. Each step plays a vital role in creating the finished products that go to market or to jewelry makers to be set.

Cleaving

Before the real work can begin, a rough diamond needs to be cut down to a size and shape that is easy to work with. To do that, diamond cutters cleave the diamond in two along the weakest point, known as the tetrahedral plane.

A mold holds The rough stone in place while the cutter grooves the plane’s edge. A steel blade is then placed into the groove and struck sharply to break the diamond in half (not necessarily equal halves, depending on the shape of the stone).

Sawing

Sometimes, cleaving is not possible, either because of the shape and size of the stone or because the cut needs to be in a different place than the tetrahedral plane. In these instances, the technique used is sawing.

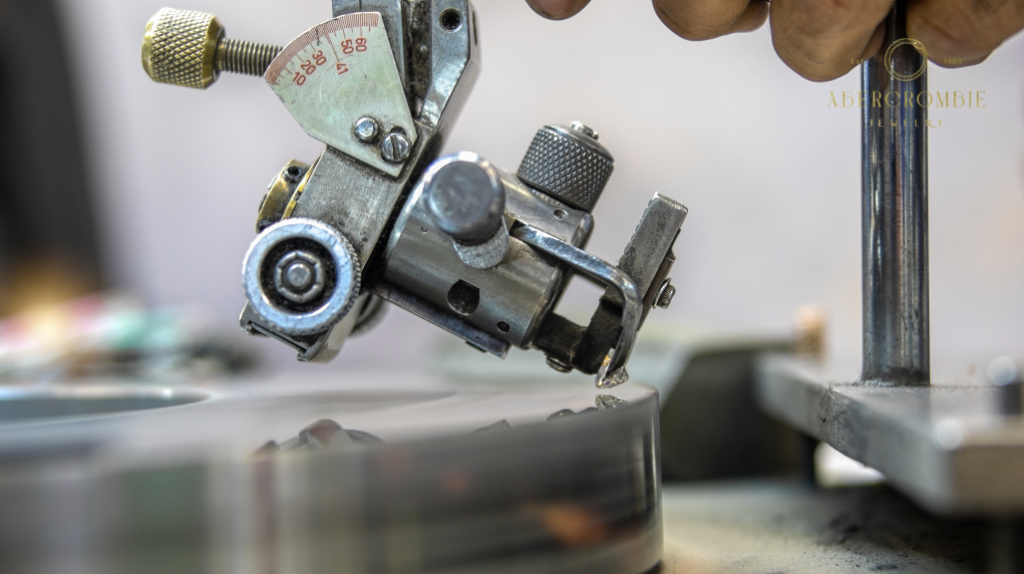

A diamond saw uses a high RPM blade to cut through the diamond, creating the table and girdle. Before starting, the cutter decides what part of the rough diamond will become the table and girdle and then makes the cuts accordingly.

Lasers are also sometimes used to saw diamonds, but it is a long, detailed process and is generally avoided unless necessary.

Bruiting or Cutting

Bruiting and cutting are both names given to the process of shaping a diamond into the desired cut. The difference between the two is how they are done- bruiting is done by hand, and cutting is done by machine.

In both cases, the diamonds are cut using other diamonds while the worked-on stone is help still in a mold (bruiting) or lathe (cutting). Each edge is rubbed down bit by bit until it is roughly the desired shape.

Polishing

The final stage of diamond cutting is the polishing- although it is a two-step process. Polishing makes the diamond look finished, with the smooth and reflective facets and edges we think of when we picture these stones.

First, the diamond is blocked- meaning the crowns, facets, cutlets, and pavilions are created. Next, the buffing or ‘brillianteering’ happens, which gives the diamond its glorious shine.

What Is the Diamond Cutting Process?

Now that you know the techniques used in diamond cutting, here is a step-by-step look at the process from start to finish.

Inspecting the Rough Stone and Planning the Cut

Before anything happens, the diamond cutter plans how and where to cut the stone. A lengthy preparation occurs where the cutter inspects the rough diamond to determine the best way to cut it and how to create a finished diamond while sacrificing as little surface as possible.

Cutting the Diamond into Pieces

Next, rough diamonds are cut into smaller pieces using the cleaving or sawing technique. This process must be handled with extreme care to keep the diamond in the best possible condition and avoid ruining valuable stone surface area.

Roughly Shaping the Diamond

Depending on the method, the cutter will either hand-cut the piece of diamond into round stones roughly in the shape of the desired finish cut. This is achieved using a spinning axle and grinding the edges down.

Polishing and Smoothing the Diamond’s Facets

The cutter then works on the stone to create the actual shape. They will smooth out the grooves and bumps to create facets, edges, and all the other characteristics of the chosen cut.

Next, everything is polished on a polishing wheel until the decided-upon brilliance is achieved.

Final Inspection

After the diamond is cut, there is a thorough final inspection to ensure it meets the requirements and standards. There are usually detailed specifications for any cut diamond that must be met before the stone is accepted.

Sometimes, after the initial inspection, the stone will go back a step to be re-polished. This continues until the cutter is satisfied that everything is perfect.

The inspection is not the same thing as diamond grading- that comes next. If the finished diamond passes the inspection, it is sent to be graded based on the four C’s:

- Cut

- Color

- Clarity

- Carat weight

Summary

A professional diamond takes careful planning, preparation, and practice to cut. Cutters use tools finished with elements of diamond to get through the incredibly tough surface, and a series of techniques come together carefully to take rough stones and turn them into valuable, beautiful gems.

The exact process of cutting a diamond varies, depending on the size and shape of the original stone and the desired finished product. It is easy to see a diamond and see nothing more than dazzling, sparkling perfection, but it is even more impressive considering what it took to get there.